Healthcare buildings are considered some of the most complex to design and build. Stakeholders of hospitals are faced with strict regulation and the need to provide emergency care and 24-hour operation. Ambulatory care centers and clinics must balance the delivery of specialty services for walk-in/walk-out attention with patient follow-up and convenience. Medical office buildings might have a lower degree of code requirements yet may be faced with higher budgetary constraints. While each building faces specific concerns, common to all these healthcare building types are issues related to infection control, energy savings, operability, flexibility, and patient and staff health and wellbeing.

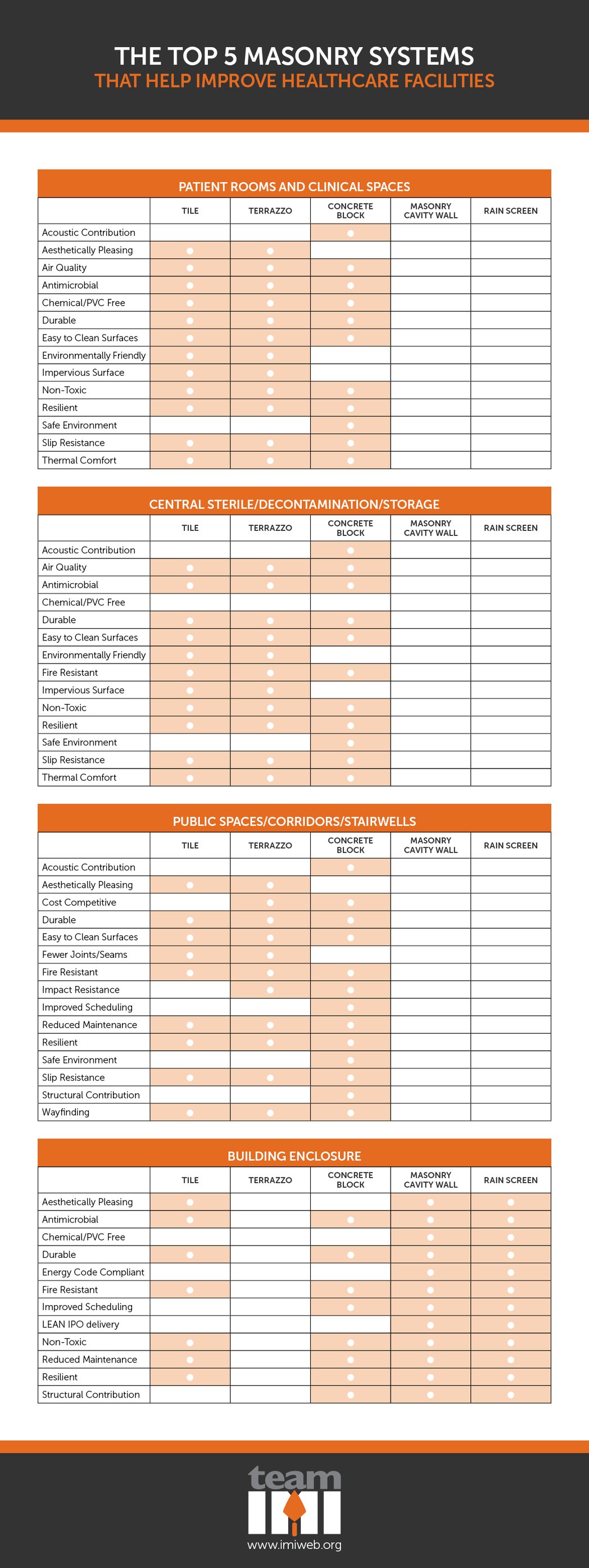

Here are 5 ways that masonry addresses these concerns:

Infection Control

Masonry cavity walls provide redundant performance layers with non-organic materials that protect against moisture and air infiltration, thereby setting the foundation for infection control by reducing the source of mold/microbe spores at the building enclosure. Materials such as brick, stone, terracotta and porcelain tiles are easily detailed for moisture and air infiltration performance. In the interior, masonry addresses infection control by providing non-organic vertical and horizontal surfaces that are easy to clean. Materials such as tile, terrazzo, polished stone, or glazed block do not serve as a food source for microbes and are impervious to damage or deterioration from cleaning agents. Commonly found in operating rooms, patient rooms, central sterile rooms, and mass decontamination areas, products such as terrazzo floors and large format interior ceramic tile provide surfaces that are durable, environmentally friendly, and able to stand up to UVs and peroxide exposure.

Energy Savings

All masonry systems address air infiltration and arm the building with proper thermal protection by allowing for continuous insulation within the masonry cavity. Masonry enclosures easily exceed energy codes and when placed on the interior, masonry materials such as tile, terrazzo, polished stone or glazed block are capable of working in conjunction with HVAC operating requirements to improve efficiency and optimize HVAC costs. This is because masonry interiors are capable of using thermal mass attributes for conduction and heat absorption to impact changes in air temperatures. By absorbing excess heat from occupants, staff, and medical equipment, masonry interiors ease cooling and heating demands and complement active design requirements for HVAC systems.

Support to Continuous operability

Masonry materials are durable, environmentally friendly, and easily available nationwide. The replacement of masonry materials can be done quickly and scheduled in a manner that does not impact patient services or treatment. Large-format interior ceramic and porcelain tiles offer better long-term performance than gypsum wall board, and the larger format provides the benefits of a smaller tile while minimizing grout joints. Newer porcelain panels are now available as sheet material and improve construction schedules while providing long lasting finishes.

Flexibility

Masonry exterior systems are possible in a range of cladding and backup configurations. Masonry provides a variety of structural solutions that concurrently reduce overall construction schedules. Newer systems such as rain screen systems are ideally suited for LEAN integrated project design models incorporating solutions for energy efficiency and green guidelines (LEED) compliance.

Patient and staff health and wellbeing

Masonry systems deliver attributes of performance that can best be described as clean, green, and lean. Clean - masonry interiors support infection control and overall patient health. Green - masonry enclosures and interiors address operational and maintenance cost through improved energy savings and facility management programs. Lean - masonry systems can be built to a high degree of quality control and cost efficiency without disruption to patient flow or operations.

Author: Maria Viteri, AIA, LEED AP BD+C